전문가들이 제공하는 다양한 정보

A Newbie's Guide To Understanding How A Hydraulic Motor Works

페이지 정보

본문

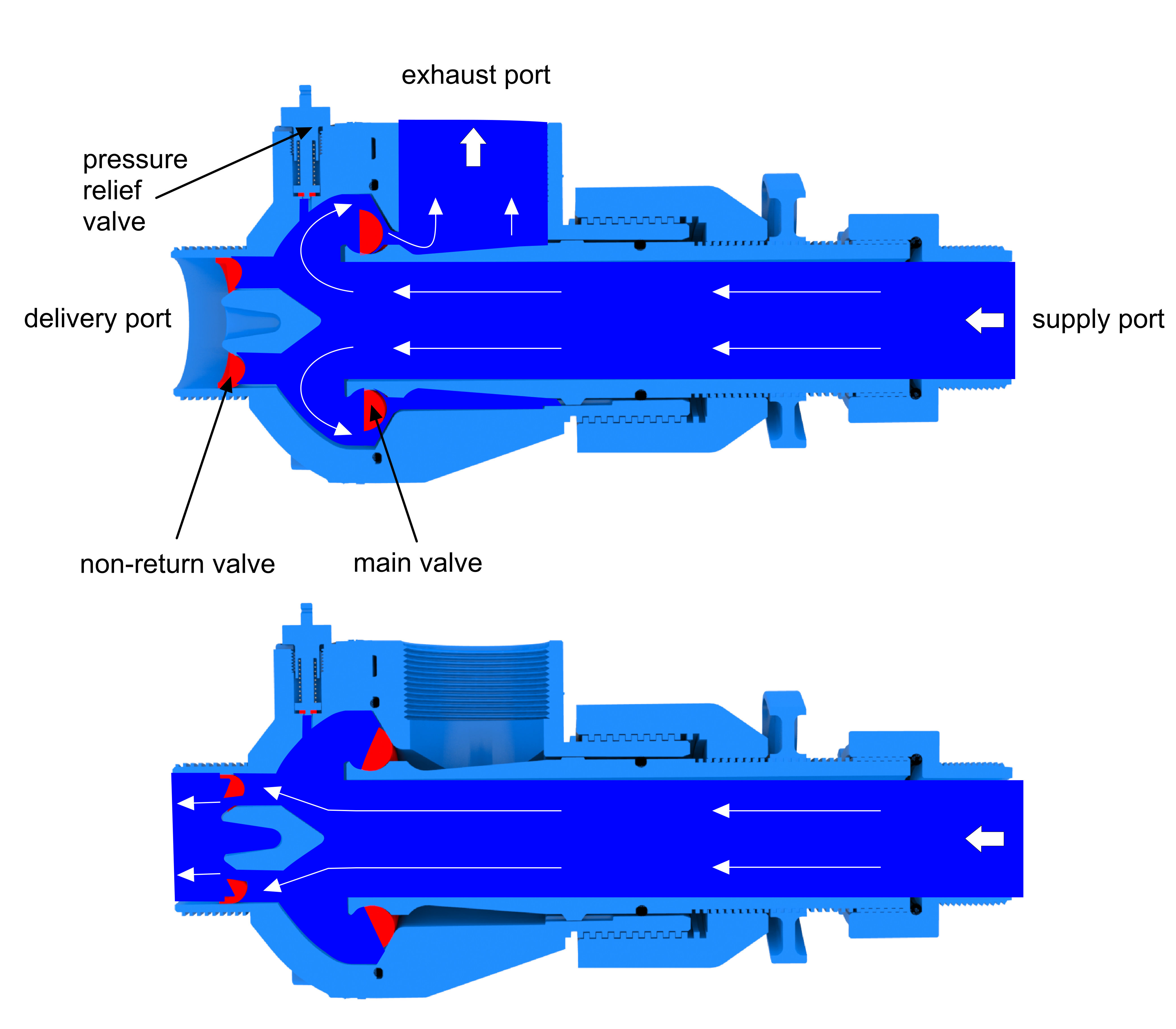

They use the pressure of the fluid to create torque and power, thereby permitting for variable speeds and torque outputs. The most typical kinds of hydraulic motors used in automotive functions embrace gear, vane, and piston motors. Every motor kind works differently but depends on varying ranges of hydraulic pressure to maneuver its inner elements. The operating precept is as follows. When the piston is at High Dead Middle, it's linked with the oil under strain from a half-groove of the distributor. During its complete descent, the piston is connected to the intake. The hydrostatic vitality is remodeled into torque energy on the shaft using the connecting rod supported by the crankshaft. When the piston is at Backside Lifeless Middle, the distributor pushed in rotation stops the oil intake for a short while. As soon as the rms and the maximum torque (together with initial and operational levels) have been calculated, they are often cross-referenced with a motor manufacturer’s performance charts to determine whether or not the motor is the required dimension. Electric motors and inner combustion motors, resembling diesel or gasoline engines, exhibit different torque traits that dictate their varying power capacities.

With over 50 years of expertise and extensive knowledge, LJM market top quality merchandise with a protracted operational life. This degree of high quality is the core of the success that LJM has achieved over time. High quality products are exactly what we are all about and want to stay identified for. Alongside the products you trust, it is also essential for LJM to have an organisation and techniques that effectively handle all processes and communications. LJM is ISO 9001 certified and works in parallel with LEAN rules to manage the production of high quality products within the most efficient and cost-efficient way attainable. These 0.1% remaining particles finest make a bed on the reservoir floor moderately than being sucked by way of the pump. However, most of the very important reservoir design elements have little to do with size however moderately function throughout the scope of their limitations. For example, hydraulic control power items operating the few capabilities on machine instrument purposes are supplied very little in ground space or surplus of electrical energy and make do with tiny reservoirs.

Try our range of pre-ready programs with clear lesson plans that have been tailored to suit all candidate levels. Created by trade consultants, these programs present the boldness and sources to ship effective training. Students will be taught in security by experimenting on a wide range of digital component and system check rigs. Interactive simulations allow them to discover the topic rules, elements, and system designs to ensure they totally perceive the theories involved. Sealing mechanisms play an important position in preventing fluid leakage. It additionally protects the motor’s inner parts from contaminants, moisture, and harsh environmental situations. Some hydraulic motors provide management choices for adjusting speed, direction, and torque. These choices may embody manual, electric, or hydraulic controls, providing versatility in different operational scenarios. Understanding the specs of hydraulic motors is important.

- 이전글Studying Cummins Dataplates For Diesel Engines (CPL Numbers & ESN) 24.08.17

- 다음글9 Days To A greater Daycare Near Me 24.08.17

댓글목록

등록된 댓글이 없습니다.